Advantages and packaging of aluminum circle plates sheets

Source:Original

Editing:Frank

Time:2018-12-13 18:02

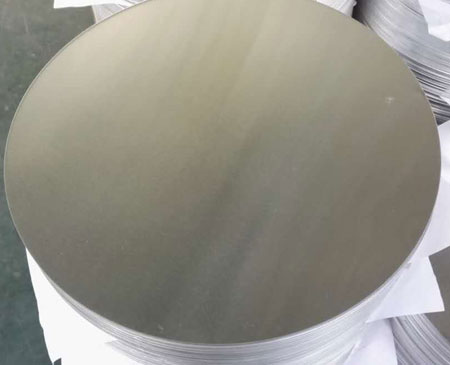

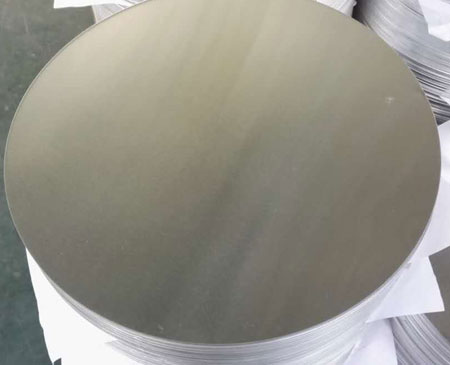

In the production process, aluminum circle plates sheets are all intelligent automatic equipment used from feeding to stamping. The coils are produced in one step and are made of aluminum discs. Therefore, the advantage of this process is that the products are not scratched, and The dimensions are very precise.

What are the advantages of signi's aluminum circle plates?

The hardness of the aluminum disc is moderate and easy to process; as we all know, the aluminum material is a moderate material, which can be formed by simple bending. If continuous high-speed stamping is carried out, it can be directly used as a finished product, which can greatly reduce production. Cycle and cost.

The advantages of aluminum circle plates sheets and how to package them

The aluminum disc has better fire resistance. Generally, the pure aluminum disc paper has no chemical substance on the surface, so it will not burn even at a high temperature of 600 degrees, and will not produce any toxic gas. It is a lot of fire protection and environmental protection. Need.

The aluminum disc has good oxidation resistance and corrosion resistance. The anodized aluminum plate chamber of the standard thickness oxide film is mainly used in the interior, because it can maintain no discoloration, oxidation and corrosion.

The aluminum discs are generally anodized, so the surface hardness is better, the scratch resistance is good, the surface is free of paint, the metal color of the aluminum plate is preserved, the modern metal sense is superb, and the product level and added value are advanced.

The aluminum disc has a strong anti-fouling effect and is very practical. Generally, we leave a fingerprint on the aluminum disc that is very clean. Aluminum discs are mainly used for metal ceilings, panels and fireproof panels.

Aluminum circle plates sheets are usually packaged in a cradle when packaged, and the packaging should meet the requirements of storage and transportation. The material used for the derrick frame is wood, and there are two wooden parts on the upper and lower sides. Generally, the height below is determined according to the needs of the forklift operation. The arc shape corresponding to the radial direction of the roll is made on the upper side of the upper wooden side and then used. The screw is fixed. Generally, the length of the screw is lower than the surface of the upper wooden arc to avoid scratching the aluminum circle blank.

What are the advantages of signi's aluminum circle plates?

The hardness of the aluminum disc is moderate and easy to process; as we all know, the aluminum material is a moderate material, which can be formed by simple bending. If continuous high-speed stamping is carried out, it can be directly used as a finished product, which can greatly reduce production. Cycle and cost.

The advantages of aluminum circle plates sheets and how to package them

The aluminum disc has better fire resistance. Generally, the pure aluminum disc paper has no chemical substance on the surface, so it will not burn even at a high temperature of 600 degrees, and will not produce any toxic gas. It is a lot of fire protection and environmental protection. Need.

The aluminum disc has good oxidation resistance and corrosion resistance. The anodized aluminum plate chamber of the standard thickness oxide film is mainly used in the interior, because it can maintain no discoloration, oxidation and corrosion.

The aluminum discs are generally anodized, so the surface hardness is better, the scratch resistance is good, the surface is free of paint, the metal color of the aluminum plate is preserved, the modern metal sense is superb, and the product level and added value are advanced.

The aluminum disc has a strong anti-fouling effect and is very practical. Generally, we leave a fingerprint on the aluminum disc that is very clean. Aluminum discs are mainly used for metal ceilings, panels and fireproof panels.

Aluminum circle plates sheets are usually packaged in a cradle when packaged, and the packaging should meet the requirements of storage and transportation. The material used for the derrick frame is wood, and there are two wooden parts on the upper and lower sides. Generally, the height below is determined according to the needs of the forklift operation. The arc shape corresponding to the radial direction of the roll is made on the upper side of the upper wooden side and then used. The screw is fixed. Generally, the length of the screw is lower than the surface of the upper wooden arc to avoid scratching the aluminum circle blank.

RELATED READ:

- Application fields of aluminum circles2015.3.19

- Application of aluminum circel in furniture2015.3.19

- what is the riply aluminum circle2015.3.19

- Application of aluminum circular plate2015.3.19

- circular metal plate2015.3.19