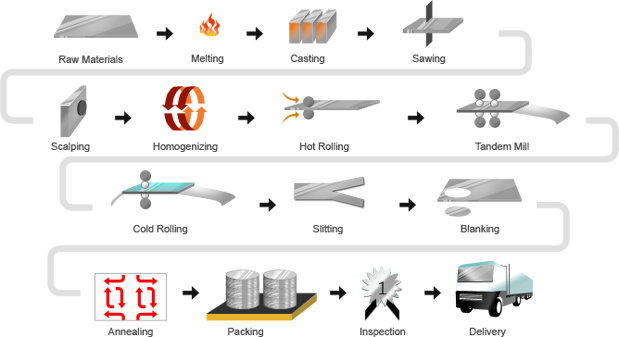

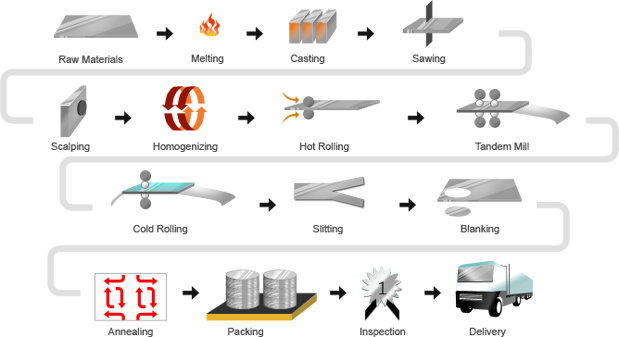

Production Process

Production Process

Ingot/Master Alloys --- Melting Furnace – Holding Furnace --- D.C. Caster --- Slab ---- Scalper --- Hot Rolling Mill – Cold Rolling Mill – Punching – Annealing Furnace -- Final Inspection – Packing --- Delivery.

Click this link to view the production video: http://youtu.be/mI5qov6pp3s

Production Step :

1. Melting and Holding Furnace

2. Holding Rolling Mesta 1+2 Stands Tandem Mill

3. Cold Rolling Davy Machine

4. Punch to Circle

5. Annealing Furnace

Production Step :

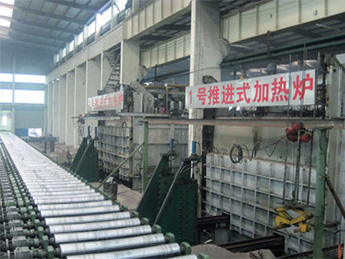

1. Melting and Holding Furnace

|

|

|---|---|

|

Pure aluminum ingots are melted and alloyed with other elements by means of master alloy such as iron, silicon, manganese and magnesium. The material is analysed and adjusted to ensure the correct composition is achieved, then degassed, filtered and transfered to casting blocks to form aluminum slabs. The slab ends would then be sawn and scalped on both sides by slab saw. |

|

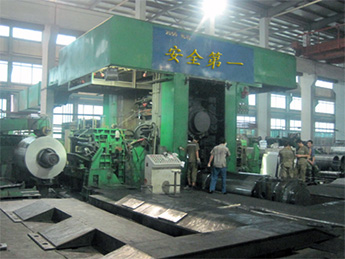

2. Holding Rolling Mesta 1+2 Stands Tandem Mill

|

|

|---|---|

|

|

|

The scalped slab is then placed inside the preheating furnace to be preheated / homogenized and made ready for the hot rolling process. The heated slab is hot rolled back and forward several times through the hot resersing mill to achieve a certain thickness prior to roll in the 1+2 Stand Tandem Mill.The finished products are hot rolled coils and plate materials for further process. |

|

3. Cold Rolling Davy Machine

|

Hot rolled coils are then processed in the Cold Rolling Machine to customers' required Thicknesses and further treated in the annealing furnaces to achieve the required temper / strength. The Cold Rolling Mill machine is equipped with Automatic Gauge Control (AGC) and Automatic Flatness Control (AFC) able to produce the closest tolerances required meeting the stringent worldwide standards. |

|---|

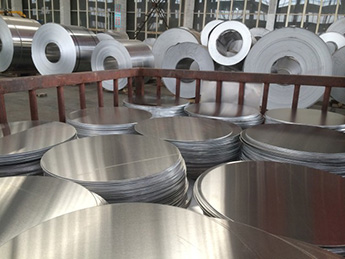

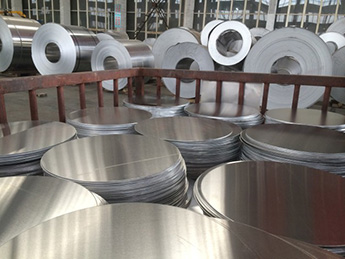

4. Punch to Circle

|

|

|---|---|

|

|

|

Hot rolled quality or cold rolled quality of aluminum strip will be sent by conveyor to the Punching machine which gets punching head with different mold to produce various kinds diameter discs as customer’s requirement. |

|

5. Annealing Furnace

|

Aluminum foil is placed in the Annealing Furnace by means of heat treatment to reach a specific temper and mechanical properties required by customers. |

|---|

RELATED READ: